A Recap of Monday 6/30/2025 – Ally L

Last Monday was Talon’s third offseason open room of the summer, and it was the last open room before Sparklefest! Sparklefest is Eden Prairie’s annual 3rd of July celebration, designed for kids and to be sensory-friendly. Every year, Talon demonstrates our robots at the event. So, we needed to make sure the robot we were bringing would work well. We decided to bring our 2024 robot Cronus to the event, because it is an amazing robot for demos. Everyone loves playing with Cronus! So, we checked all of the hardware and software on the robot, and decided it was ready to go. Read about how the event went here!

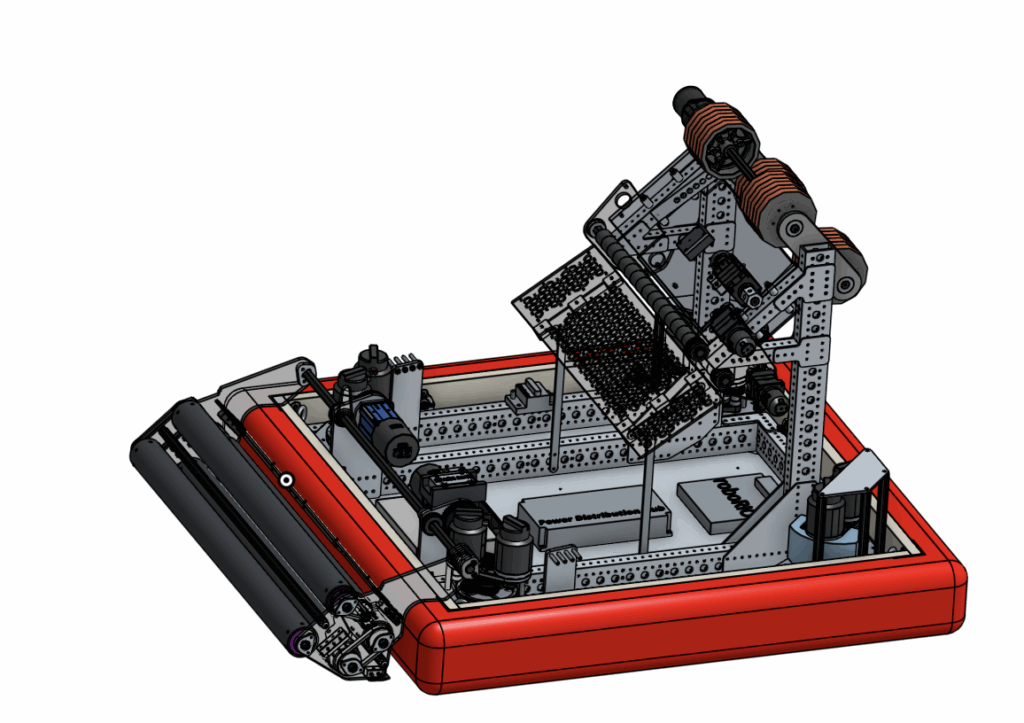

On Monday, we also continued the work on Drift-sco from the last few weeks. The work was mostly on the programming for Drift-sco. We seem to have gotten all of the weird electrical problems figured out!

Cronus After Sparklefest

This Monday was the fourth offseason open room, and it was mainly focused on fixing Cronus after Sparklefest. While the event went great, with kids playing catch as well as learning about how the robot works, there were issues with one swerve module on Cronus by the end of the event. We swapped out one of the motors of the swerve module while we were at the event, and explained how some of the robot’s electrical components work to some very curious children as we repaired them. However, that did not fully fix the module, so at open room, we had to figure out what was wrong.

When we arrived at open room on Monday, we began testing all of the swerve modules on Cronus to see if any of the others had problems. The only one that had issues was the front left module, which had been broken at Sparklefest. One of the motors was not running properly (specifically, the one we replaced during the event) and the gearbox was making strange clicking noises.

It was very important to understand how swerve modules work in order to troubleshoot these strange problems. Swerve drive is a type of FRC drivetrain where each wheel is powered by two motors. One motor changes the wheel’s direction, so that the robot can go forwards or sideways, and the other rotates the wheel, so that the robot will move. It’s a lot like shopping cart wheels, which can twist in any direction while the wheel rolls on the ground. The difference is that swerve drive controls all of the motion involved, using those two motors and a complex system of gears to transfer the movement.

Now that we’ve explained more about swerve drive, we can go more into detail on what broke. The front left turn motor, so the motor in that module that controlled what direction the wheel was facing, was not running. It would turn on, with the lights flashing the right colors, but it would not rotate. The strange clicking noises, though, were coming from the drive motor and gears, which make the wheel roll. So, both parts of the swerve module had completely separate issues.

The first thing we did was remove the module from the robot and investigate the gearbox. While we could not find the source of the strange noise. We did find out that it was missing a spacer, which helps to hold the wheel in place. Thankfully, it was a really quick fix, and after removing only three bolts we had that solved. Sadly, the gearbox was still making the strange clicking and grinding noises. We used some Brakleen to scrub anything that could be stuck from between the gears, and the gearbox was fixed!

The only problem left was the turn motor, so we put the module back on the robot and plugged everything back in to begin testing. We updated the firmware of the motor, to make sure it was able to run code correctly, and then tested it. While that didn’t work, we got the strangest error message, which made everyone laugh. When we tried to send instructions to the motor, the message “CAN Frame too stale” popped up. “Someone forgot to put the CAN bus in the fridge,” one of the programmers said, and someone asked, “Who forgot to close the bag of CAN?”

That definitely seemed like an issue in code, though, so we replaced the code on the robot (we sent the same code that it was supposed to have with no changes, we just wanted to make sure the robot didn’t have the wrong code). Nothing happened. We decided to try a different motor. Nothing worked, so we went back to the motor we had been using before.

Eventually, we looked at the PID constants set for the motor. They help us tune how we control the motor, and help with automation. We found out that no one had set them yet!

During the quick fix at Sparklefest, they set all of the PID constants to zero, which was causing our strange issues with the motor! Our wonderful programmers set the PID constants correctly, and Cronus drove perfectly.

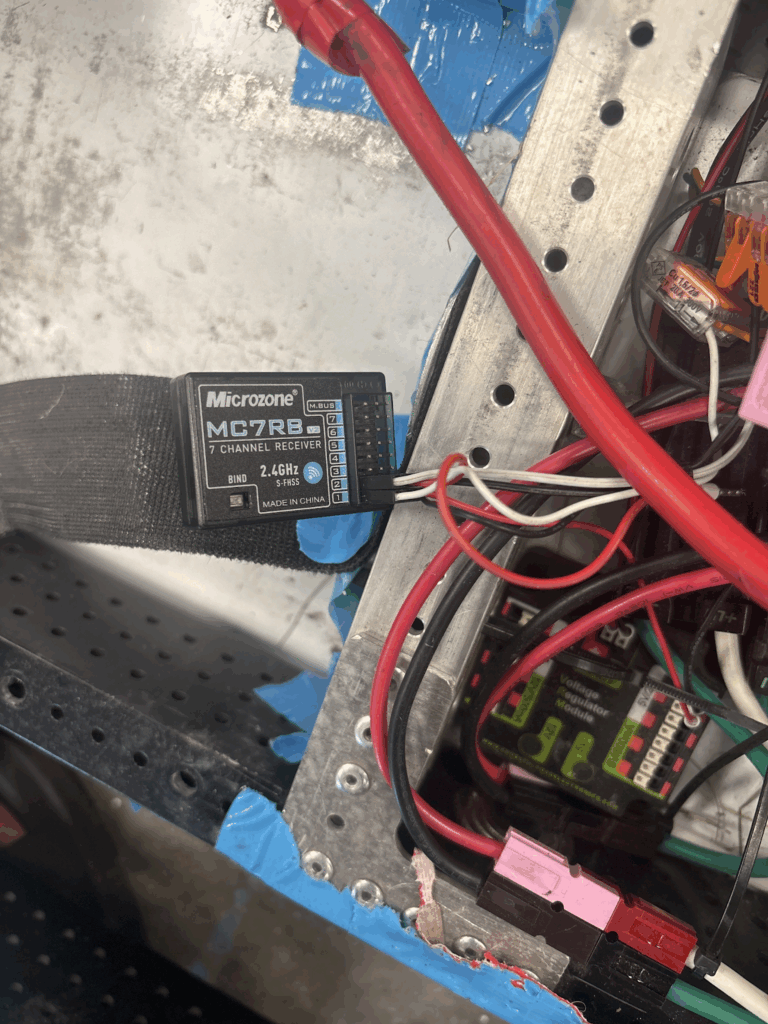

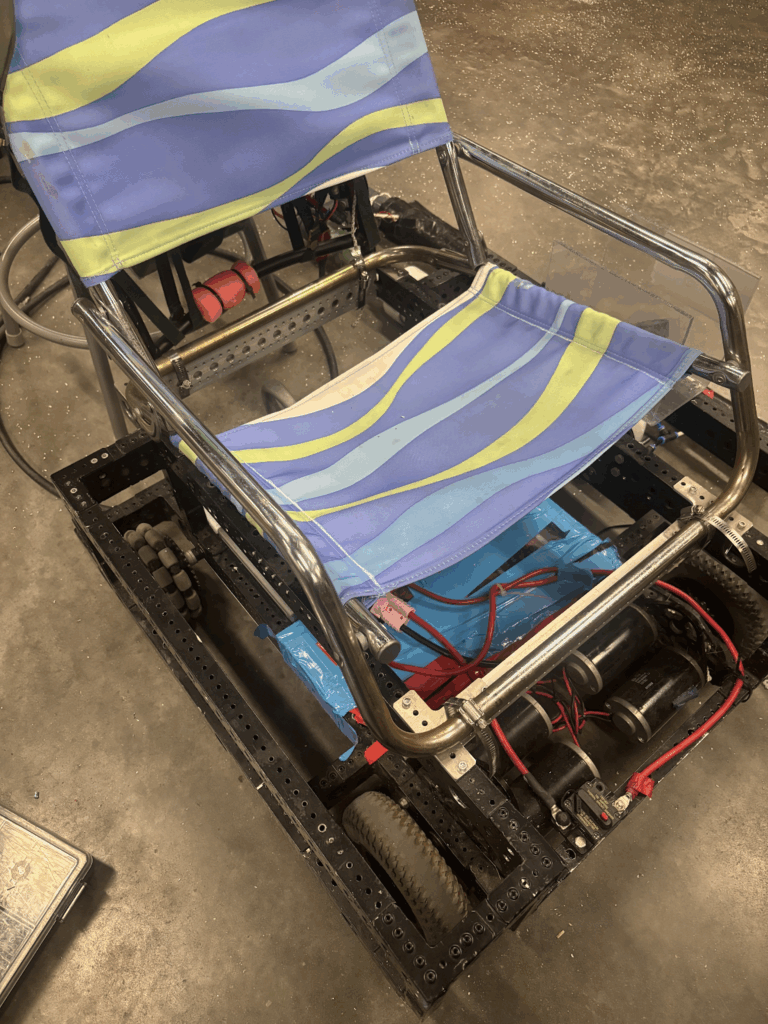

Chairbot

A more fun part of the open room was working on one of our simpler demo robots, Chairbot. Chairbot is a simple tank drivetrain, with four wheels that can go forwards and backwards, and a chair strapped to the top so that people can go for rides. To make this more fun, a senior installed an RC car receiver in the robot so that we could control Chairbot like an RC car. However, he has since graduated! We installed someone else’s RC car receiver in the robot, so that he can take his home, but we also made it so that the receiver was more interchangeable.

Chairbot is designed to drive outside in the grass, so the electronics must be waterproof. This made exchanging the receiver a much longer process than it could be. So, we designed a small waterproof box to allow for the receiver to be quickly swapped. Then, we re-waterproofed the robot, as previously we had to remove all of the waterproofing to access the receiver. We tested this by driving the robot in the light rain outside the robotics room, and it worked perfectly!

Stay Connected With Us During The Entire Season!

If you want to stay connected with the team during the entire season, feel free to check out our social media pages: